The transformer health index (THI) represents a paradigm shift in how the power industry approaches asset management for critical grid infrastructure. At its core, CIGRE A2.44 defines the transformer health index as “an overall indicator describing the condition status of a transformer that the decision maker can use to define and prioritize the required action.” This definition, while concise, encapsulates decades of engineering practice distilled into a single actionable metric.

The asset management problem

Power transformers are among the most capital-intensive assets in electrical grids. Replacement costs range from hundreds of thousands to millions of euros depending on capacity and voltage class. A 400 MVA generator step-up transformer in a power station represents not only a multi-million euro capital investment but also carries catastrophic failure risks:

- Unplanned outages causing grid instability

- Cascading failures across interconnected systems

- Fire hazards and safety incidents

- Environmental contamination from mineral oil release

- Extended downtime affecting power generation or distribution

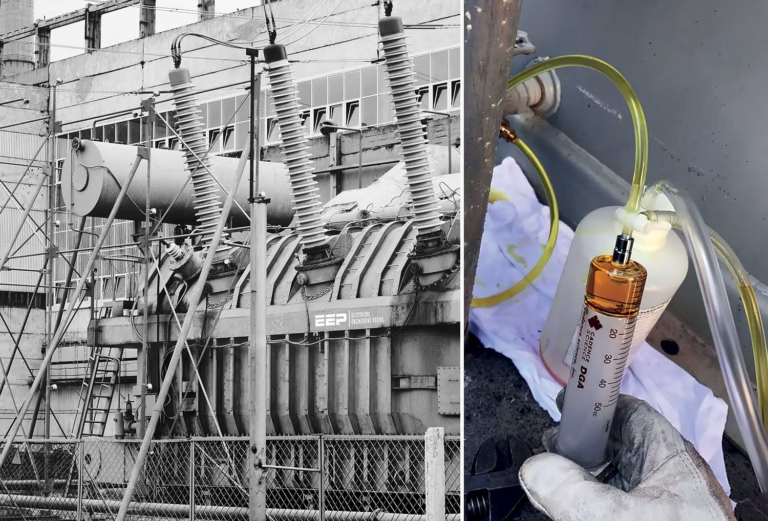

Traditional diagnostic complexity

Traditional diagnostic approaches rely on subjective expert interpretation of 60+ individual parameters. These include dissolved gas analysis results, oil quality metrics, electrical test data, thermal imaging, partial discharge measurements, and operational history.

This complexity creates several critical problems:

Subjective interpretation: Different experts analyzing identical data may reach contradictory conclusions due to the inherently subjective nature of rule-based interpretation methods.

Fleet-scale intractability: Prioritizing maintenance actions across a fleet of hundreds or thousands of transformers becomes computationally impossible when each asset requires manual analysis of dozens of parameters.

Low diagnostic accuracy: Industry studies report 35-56% accuracy for traditional rule-based methods. This variance introduces unacceptable risk into capital allocation decisions.

The health index addresses these problems by reducing multidimensional diagnostic complexity to a single, standardized numerical score. This enables objective comparison, reproducible decision-making, and fleet-wide risk prioritization.

What is Health Index: technical definition

The health index is not simply a weighted average of test results. CIGRE TB 630 and TB 761 establish it as a composite indicator derived from condition monitoring data through validated methodologies. These methodologies account for failure mode physics, aging mechanisms, and operational stress factors.

Health Index scale and interpretation

The index operates on a 0-100 scale where higher values indicate better condition. The standardized interpretation framework defines five condition bands:

- 90-100: Excellent – Continue routine monitoring

- 75-89: Good – Standard diagnostic intervals

- 60-74: Fair – Increased monitoring frequency

- 40-59: Poor – Evaluate for intervention within 12 months

- 0-39: Critical – Immediate action required

These bands correspond to recommended action timelines. Assets in Critical condition require immediate intervention, while those in Excellent condition continue routine monitoring cycles.

What Health Index measures (and what it doesn’t)

The health index quantifies:

- Current condition state based on observable diagnostic evidence

- Relative risk comparison across transformer populations

- Degradation trajectory when trended over time

The health index does NOT:

- Directly predict remaining useful life (though trending provides failure risk trajectory)

- Replace detailed root cause failure analysis when specific fault modes are identified

- Eliminate the need for engineering judgment

Rather, it provides decision makers with an objective foundation upon which to apply operational context, risk tolerance, and resource constraints.

Health Index methodology: from data to decisions

Calculating a valid health index requires three technical components: feature selection, weighting methodology, and validation against ground truth data.

1. Feature selection

Feature selection identifies which diagnostic parameters contribute meaningful information to condition assessment. CIGRE methodology emphasizes parameters with demonstrated correlation to failure modes:

Dissolved Gas Analysis (DGA):

- H2, CH4, C2H6, C2H4, C2H2 indicating thermal decomposition

- CO, CO2 reflecting cellulose degradation

- Gas ratios for fault type classification (Rogers, Duval)

Oil Quality Metrics:

- Moisture content affecting dielectric strength and cellulose aging rate

- Acidity reflecting oil degradation and oxidation byproduct accumulation

- Interfacial tension (IFT) indicating contamination levels

Complementary Indicators:

- Furfural concentration quantifying cellulose polymerization degree

- Tan delta or power factor for dielectric property assessment

- Operational age and load history

Not all 60+ available diagnostic parameters contribute independent information. Hydrogen and methane concentrations, for example, exhibit strong correlation since both gases generate from similar thermal degradation mechanisms. Effective health index methodologies eliminate redundant parameters through correlation analysis, reducing input complexity while maintaining diagnostic accuracy.

2. Weighting methodology

The weighting methodology determines how individual parameters combine into the final index value.

Traditional approaches use linear weighted sums with weights derived from expert elicitation. This means asking experienced engineers to assign relative importance to different test results.

Modern methodologies employ machine learning techniques that extract optimal weights directly from historical data. These methods identify which parameter combinations best correlate with subsequent failures or successful operations.

Advanced implementations use non-linear models that capture complex interaction effects. For example, the combined impact of elevated moisture and high acidity exceeds their simple sum due to synergistic aging acceleration.

3. Validation against ground truth

Validation represents the most technically demanding aspect of health index development. A methodology that produces a health index of 45 for a transformer must demonstrate through empirical evidence that assets with that score exhibit measurably higher failure probability than assets scoring 75.

This requires:

- Large datasets linking historical diagnostic measurements to observed outcomes

- Statistical analysis proving correlation significance

- Cross-validation across different transformer populations to confirm the methodology generalizes beyond the training dataset

Health Index calculation process

The transformation from raw diagnostic data to health index involves several processing stages:

Data acquisition: Captures condition monitoring results, typically DGA performed annually or semi-annually, periodic oil quality testing, and thermal/electrical measurements during outages or online monitoring.

Data normalization: Accounts for measurement unit differences and scales parameters to comparable ranges.

Missing data handling: Addresses the practical reality that complete diagnostic datasets rarely exist, particularly for older transformers with incomplete testing history.

Feature engineering: Derives secondary indicators from raw measurements. Gas ratio calculations (Rogers ratios, Duval triangle coordinates) provide fault type classification. Rate-of-change metrics identify accelerating degradation even when absolute values remain within acceptable limits. Age-adjusted baselines account for the fact that 3 ppm acetylene in a 5-year-old transformer carries different implications than the same concentration in a 40-year-old unit.

Aggregation: Combines normalized, weighted features into the final index score using linear or non-linear mathematical models.

Output interpretation: Translates the numerical score into maintenance recommendations. This is where the health index delivers its primary value: objective prioritization.

Condition-based maintenance with Health Index

The health index serves as the foundational metric for condition-based maintenance (CBM) strategies. Traditional time-based maintenance schedules transformers for major overhauls at fixed intervals (every 10 years, for instance) regardless of actual condition. This approach either performs unnecessary work on healthy assets or delays critical intervention on degraded units that happen to be younger than the scheduled maintenance age.

CBM paradigm shift

CBM shifts the paradigm: maintenance occurs when condition metrics indicate need, not when arbitrary time thresholds expire. The health index makes this operationally feasible by providing the standardized condition metric required to trigger maintenance workflows.

An organization might establish a CBM policy stating:

- Any transformer with health index below 50 enters a six-month evaluation period for repair-or-replace decision-making

- Units scoring 50-60 receive accelerated diagnostic monitoring to track degradation rate

- Assets above 75 continue standard annual monitoring cycles

Fleet-level capital planning

This integration extends beyond individual asset decisions to fleet-level capital planning. Trending health index distributions across a transformer population reveals emerging fleet-wide issues. If 15% of a manufacturer’s units from a specific production year show declining indices, it suggests systematic quality or design problems requiring proactive mitigation.

Comparing health index distributions between different voltage classes, cooling types, or operational environments identifies risk concentrations requiring targeted resource allocation.

Risk-based investment prioritization

The health index enables sophisticated risk modeling. By correlating historical failure events with pre-failure health index values, organizations develop probabilistic failure prediction models.

A transformer scoring 35 might exhibit 8% annual failure probability based on empirical data, compared to 0.5% for a unit scoring 75. Multiplying failure probability by consequence (replacement cost plus outage impact) yields expected annual risk in monetary terms. This provides a common language for comparing transformer risk against other grid investment priorities.

Technical limitations and practical considerations

Despite its utility, the health index faces inherent technical limitations that practitioners must understand.

Information loss from dimensionality reduction

The index provides a single-number summary of complex, multidimensional condition data. Information loss is inevitable. Two transformers with identical index values may have markedly different diagnostic profiles requiring different maintenance approaches.

One might show elevated thermal gases with normal moisture, the other high moisture with minimal gas generation. The index identifies both as equivalent risk, but optimal interventions differ substantially.

Temporal resolution constraints

Most health indices derive from annual or semi-annual diagnostic data, providing at best a snapshot of condition at testing moments. Rapid degradation occurring between diagnostic intervals remains undetected until the next scheduled assessment.

This limitation motivates integration of online monitoring systems that continuously track key parameters, though incorporating high-frequency online data with low-frequency offline diagnostic results introduces methodological complexity.

Data quality dependencies

The index assumes diagnostic data accuracy and representativeness. Sources of error include:

- Dissolved gas samples contaminated during collection

- Oil tested immediately after a through-fault event

- Measurements from non-representative tap changer compartments

Data quality assurance represents an essential but often overlooked aspect of reliable health indexing. This includes validating measurement procedures, detecting outliers, and confirming sample chain-of-custody.

Root cause analysis limitations

The health index quantifies current condition but provides limited insight into failure mode specifics or root cause mechanisms. A critically low index indicates severe degradation but doesn’t definitively specify whether thermal aging, moisture ingress, partial discharge activity, or mechanical damage drives the condition assessment.

Detailed diagnostic interpretation remains necessary for developing effective remediation strategies.

CIGRE TB 761: the industry standard

CIGRE Technical Brochure 761 provides the authoritative framework for transformer health index implementation. Published by CIGRE Study Committee A2 (Transformers), TB 761 builds on earlier work in TB 630 to establish:

Standardized definitions for health index calculation and interpretation across different utility organizations and equipment manufacturers.

Validation requirements ensuring health index methodologies demonstrate empirical correlation with observed transformer performance and failure rates.

Integration guidelines for incorporating health index into broader asset management systems, risk models, and capital planning processes.

Best practices for data collection, quality assurance, and diagnostic testing programs that support reliable health index calculation.

Organizations implementing health index methodologies reference CIGRE TB 761 to ensure alignment with industry best practices and enable benchmarking against peer utilities.

Real-world implementation: AI-driven Health Indexing

Modern implementations leverage machine learning to automate health index calculation at scale. RONIN AI, developed by Seetalabs, demonstrates how artificial intelligence transforms the health index concept into an operational reality.

The system processes 14 key diagnostic parameters (reduced from 63+ traditional indicators through feature selection) to generate CIGRE-compliant health index scores in under 6 seconds per transformer. This enables utilities to assess entire fleets rapidly, identifying high-risk assets for immediate attention while confirming low-risk units can safely continue service.

By training on thousands of real-world transformer datasets, AI-driven approaches achieve higher accuracy (77% vs. 35-56% for traditional rule-based methods) while eliminating subjective interpretation variance. The result is objective, reproducible risk ranking that supports defensible maintenance prioritization decisions.

Conclusion: the future of transformer asset management

The transformer health index, as defined by CIGRE A2.44 and detailed in TB 761, represents more than a diagnostic tool. It embodies a fundamental shift toward data-driven, objective asset management for critical power infrastructure.

By condensing multidimensional condition complexity into a standardized metric, it enables:

- Reproducible decision-making across different engineering teams

- Fleet-wide risk prioritization based on objective data

- Condition-based maintenance strategies that optimize capital allocation

- Risk quantification in financial terms for executive decision-making

The index does not eliminate engineering judgment or detailed diagnostic analysis. Rather, it provides decision makers with an objective foundation upon which to apply operational context, risk tolerance, and resource constraints.

As the power industry confronts aging transformer fleets, increasing grid complexity, and tightening reliability requirements, the health index offers a technically rigorous, economically defensible methodology for managing transformer populations at scale.