In April 2020, a utility registers ultimate failure of a 100 MVA, 100/110 kV generator step-up (GSU) transformer. Built in 1980, the transformer was prone to particularly high level of hydrogen, ethylene, and acetylene presence in oil. The utility recognizes it as a high-risk asset and ensure frequent filtration and degassing of oil. However, neither of these steps could determine the actual reliability and/or prioritize plans for risk management.

Transformer condition through data

The utility would follow routine oil-diagnostic tests with recommended frequency with an exception towards dissolved gas analysis (DGA). The team relies heavily on DGA reports for quantitative assessment of transformer using IEEE and IEC standards. The utility uses a more manual approach which eliminates the scope of real-time triggering by making the monitoring more “time-based”. Apart from the DGA reports, occasional data on moisture and paper degradation was also available. Due to no visible damage, any information on leakages is also unavailable.

Gas trends and fault interpretations

Since the previous outage in 2016, the utility started noticing unusual gassing tendencies in the main tank oil. Three gases namely, hydrogen, ethylene, and acetylene are reaching alarming levels. Hydrogen is one of the first fault gases to form in transformer oil. Furthermore, it increases with temperature.

Typically, DGA and gassing trends are pivotal components of strategic condition assessment. It gives partial insight of potential fault modes and their location without additional remarks on the technical urgency. With the unexpected rise in combustible gases, the utility was pressed on response time to save the asset from abrupt failure. Furthermore, with adequate information the utility can do a better job in downtime planning. Therefore, Seetalabs offered to highlight asset reliability and provide an actionable plan through key condition monitoring data using Ronin AI.

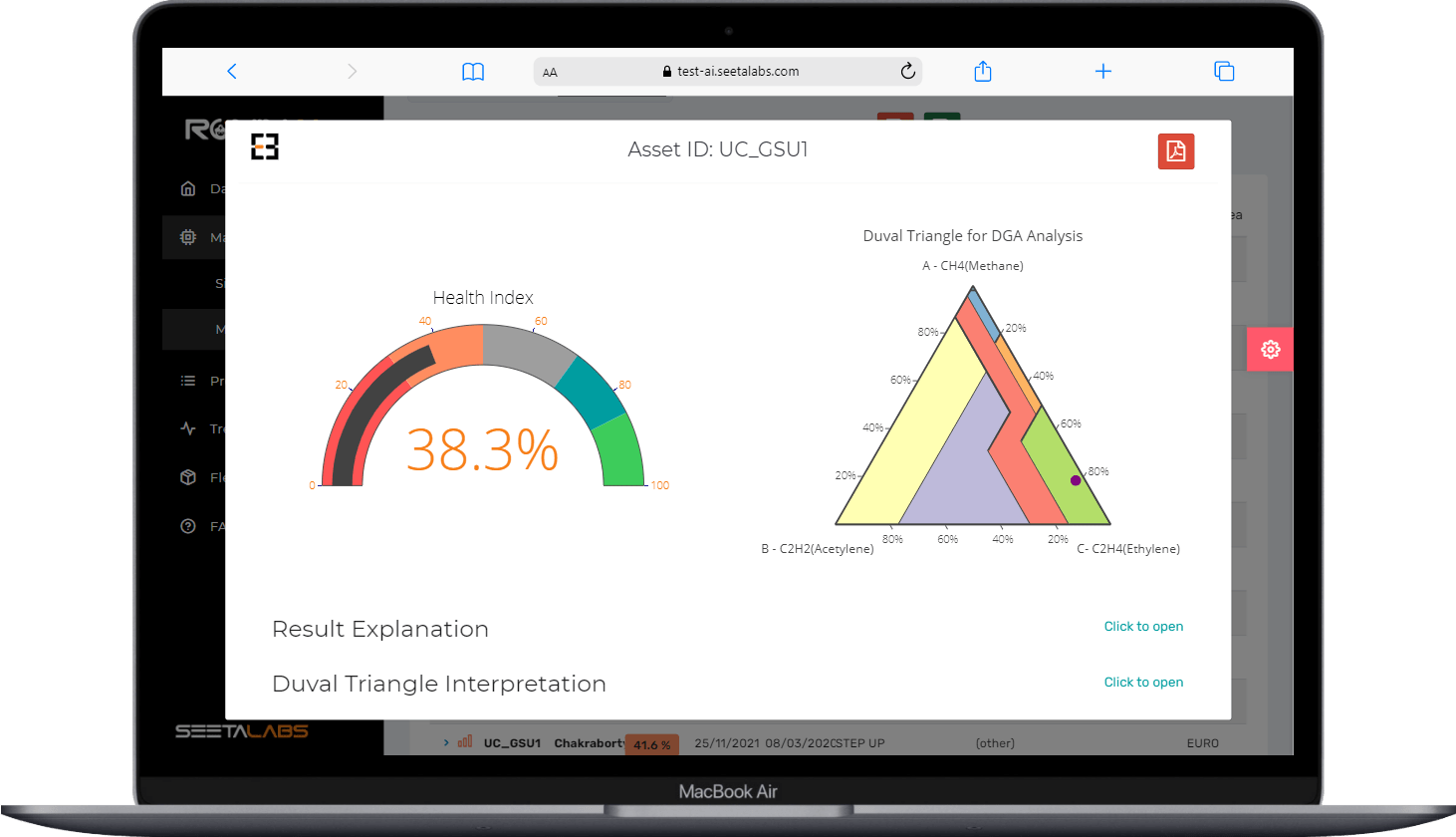

The condition monitoring data was uploaded in to the Ronin AI Dashboard to obtain a numerical score called transformer health index to determine the likelihood and potential time of failure of assets. It will allow the asset managers to rank their transformers, particularly in large fleets, on the basis of reliability and prioritize maintenance actions.

Ronin AI discoveries

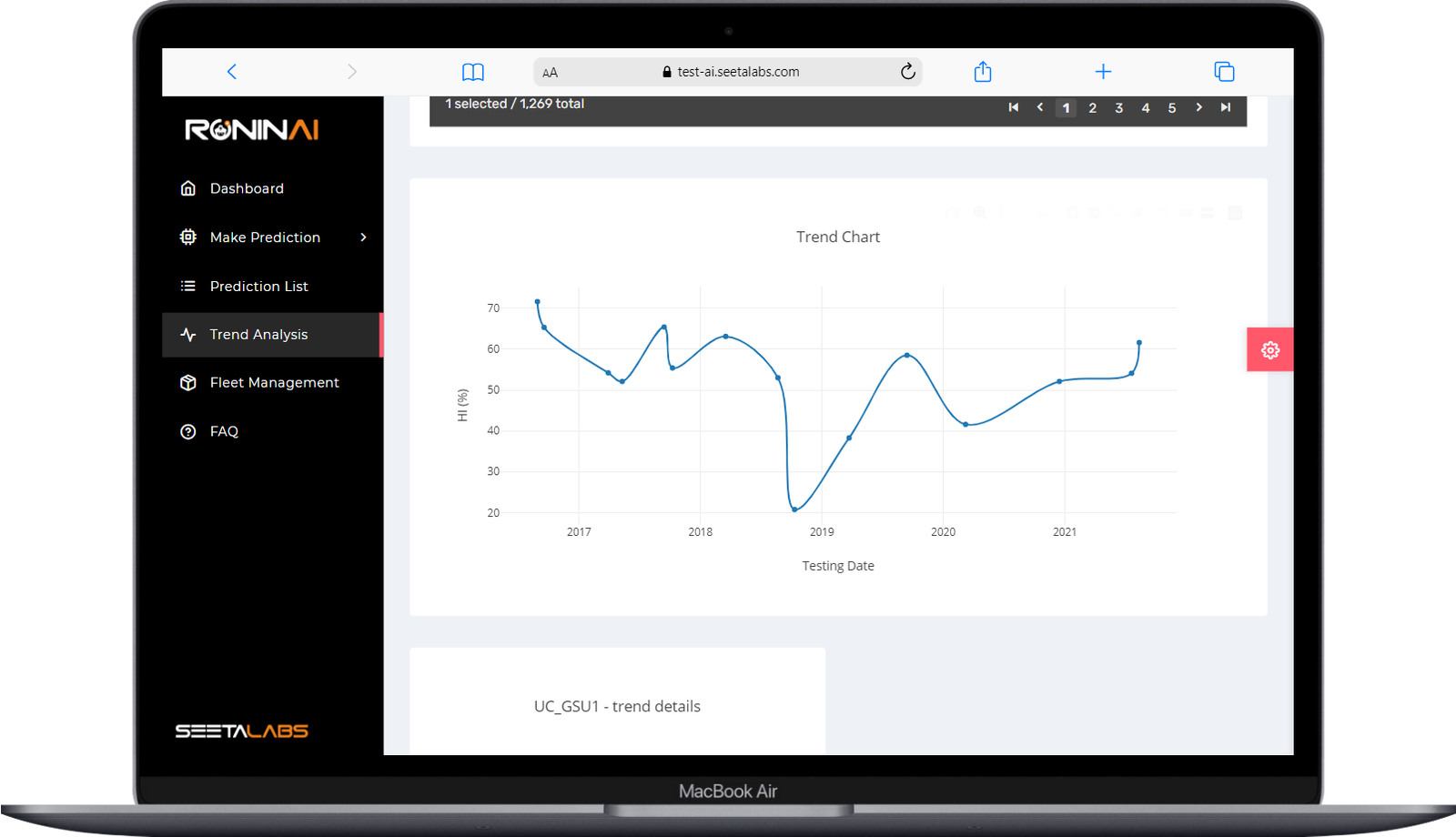

As anomalies were first reported in the latter half of 2016, a complete and updated data set from 2016 till 2021 was issued to us. This data set contains periodic dissolved gas analysis and most of oil quality parameters. Only interfacial tension (IFT) was never reported. Based on this data an instantaneous health index and corresponding trend was obtained for the given asset.

The health index score of this transformer dropped from 71.6% to 63.8% within 20 days in the middle of 2016. In terms of index definition, this means that the transformer dropped from a good to fair status. The drop was caused due to an increase in dissolved gas-in-oil concentrations. This was immediately followed by degassing protocols.

Despite standard maintenance actions, the health index reported at the beginning of 2017 dropped further to about 50%. By 2019, the health status was dangerously low (about 38%) with no clear insights on the overall reliability of this asset.

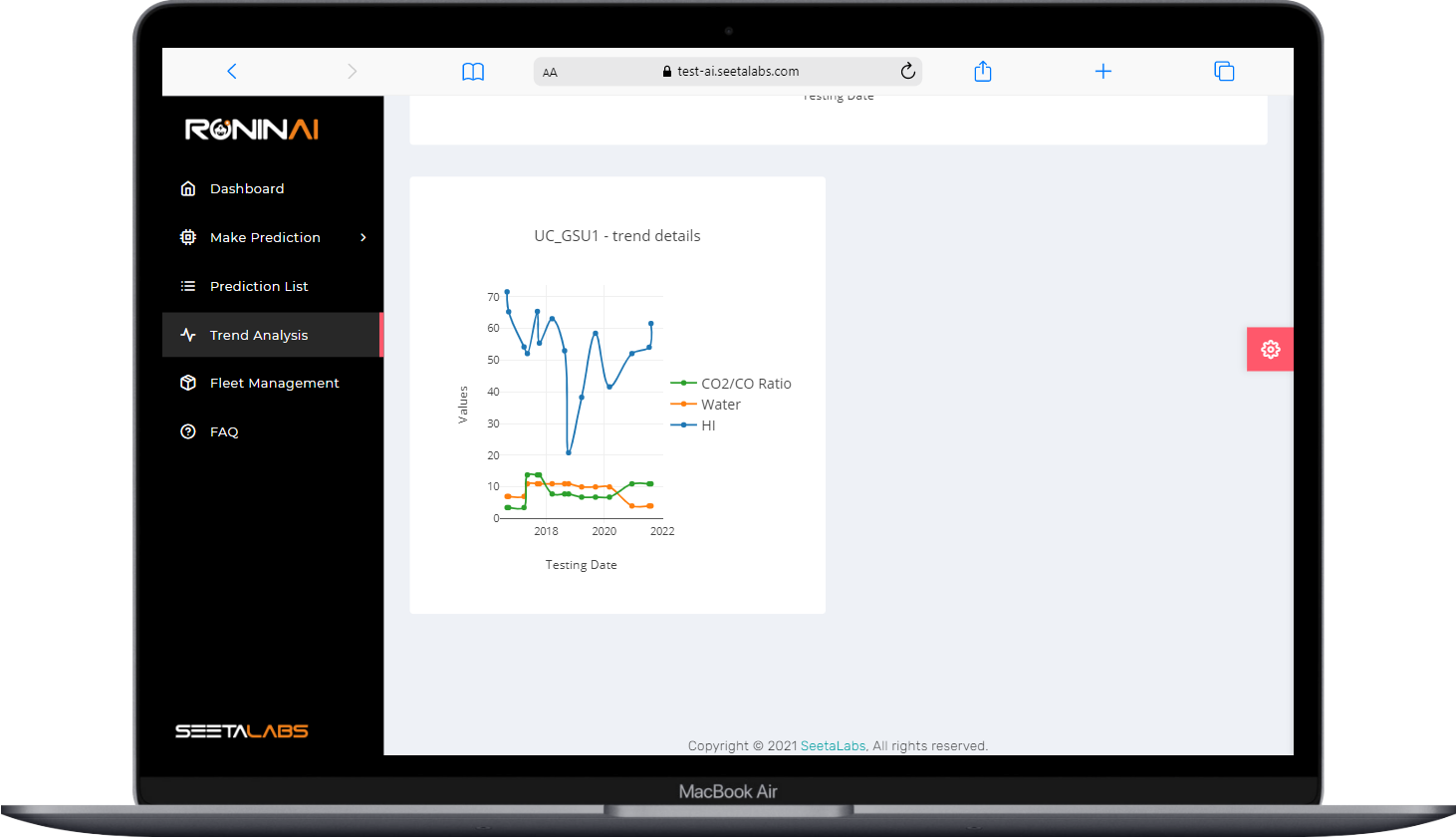

The condition monitoring data particularly CO2/CO gas ratio, 2-FAL and water were higher than the acceptable limits every time the health index dropped.

The succeeding oil treatments without any major maintenance of the asset did not improve the health of asset as it dropped from fair to poor condition by 2019. By definition, this would mean that insulation is degrading rapidly due to internal heat accumulation and requires intervention. It also indicates that oil treatment as a primary response is insufficient.

Conclusions

This means that a decrease in reliability and increased risk is because of inevitable ageing. The internal faults have not been repaired correctly and the operational credibility of the asset will continue to decline if thorough investigation is not performed. Based on the latest data, the transformer has a health index score of 61.6% within a fair range. However, it should be thoroughly investigated within six months to avoid replacement and abrupt failure of the asset.