Globally, transformer experts agree that a health index cannot indicate how rapidly the transformer condition may worsen and the type of action needed. Rather it indicates how “unhealthy” an asset is. This begs for two questions, (i) what is the use of health index, and (ii) can one health index algorithm deliver all objectives?

Understanding transformer health indexing

CIGRE experts emphasizes that a transformer health index can be a powerful fleet screening tool. It allows quick assessment of each asset within the fleet and ensure further investigations based on intervention priority. For example, a health index is useful to plan maintenance activities on a transformer fleet containing very strategic assets. Conversely, some asset managers use health index to repair and/or replace transformers within a fleet.

CIGRE also recognizes composite indexes as a combination of replacement and repair or refurbishment results. However, the technical and financial detailing necessary to achieve this can be overwhelming. Therefore, an asset manager’s interest in evaluating the benefits of using Ronin AI for transformer health indexing purposes is only natural.

Read our blog post for an elaborate discussion on the transformer health index and how various factors can be lead to bias thus limiting its scope.

Exploring Ronin AI as a transformer health solution

Seetalabs’ Ronin AI helps to rank transformers using a health index score that focuses on reliability and potential time left for a total failure of their asset. It uses a well-trained supervised machine learning algorithm for its predictive approach.

A comprehensive decision requires further technical analysis and sense of urgency to assign appropriate interventions to optimize reliability and availability of the asset. In case of replacement, it is necessary to analyze the type, nature, and extent of damage through suitable failure mode analysis. If such elaborate information is readily available with the asset manager, then a combined reliability-replacement assessment can identify the scope of repairs or refurbishment as well.

For example, the generation of various gases within the typical oil-immersed cellulosic insulation complex of transformers is quite common. Factors such as oxidation and overheating are catalytic towards the degradation of oil and cellulosic material thereby generating various by-products. Some of these by-products, particularly in the gaseous state, dissolves in transformer oil causing various faults. Meticulous condition monitoring of transformers using dissolved gas analysis (DGA) ensures early forecasting of fault inceptions.

The dissolved gas analysis (DGA)

The dissolved gas analysis (DGA) is a method for identification of transformer faults by measuring concentration of by-product gases such as hydrogen (H2), methane (CH4), ethane (C2H6), ethylene (C2H4), acetylene (C2H2), carbon monoxide (CO) and carbon dioxide (CO2). An international standard ensures that DGA can improve the safety and reliability of operating transformers by early detection of incipient faults. It improves strategic predictive maintenance and optimizes operational costs. Various field, laboratory, and on-site gas analyzers operating on-line or off-line modes are now commercially available for this purpose. While it acts as a tool for basic risk management, DGA alone cannot quantify the asset risk and recommend actions over a defined timeline.

A technical brochure recommends the use of single gas (such as hydrogen) monitors on relatively “healthy” transformers. However, to determine transformer “healthiness” without comprehensive DGA is challenging even by health indexing strategy. Further evaluation of the gassing tendencies can pin-point the severity and potential location of the problem. Similar diagnostic tests to ensure oil quality can help in drawing critical and comprehensive insights about the existing state of transformer. However, it cannot predict future trends and provide a timeline of intervention. Furthermore, in case of large fleets the data volume from all necessary diagnostic tests could be overwhelming and may require additional assistance to derive critical decisions.

Despite its significance, health indexing solely based on DGA results could be partially misleading. Conversely, complete and updated DGA results from all transformers were easily available for any investigation.

An asset manager possess the afore-discussed knowledge and as a user understands the Ronin AI capability of handling and compensating for the missing information. Consequentially, the accuracy, accountability, and reliability of health index score and their decision making capacities improve in just 3 steps.

Case study of a 250 MVA, 400 kV autotransformer

Consider a fleet of seven auto-transformers that belong to a transmission utility. Each assets has peculiar gassing tendencies and despite the sparse information the oil quality of these assets is surprisingly good. The asset manager wishes to rank their transformers to evaluate the efficacy of their past maintenance actions and decide future activities. There are two most noticeable details in this case study. Firstly, four out of seven transformers do not have complete data of their oil quality. Secondly, the concentrations of various key gases are particularly high for all transformers. Additional details from the asset manager on the maintenance, operational or performance history of these transformers was not available to Seetalabs’ experts at the time of investigation.

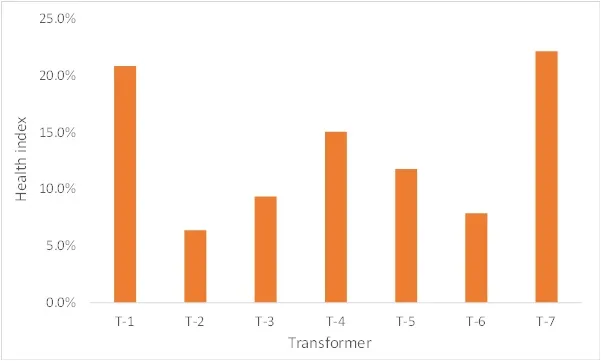

Upon uploading the available data, Ronin AI predicts the health index of each asset as shown in the image below. While all of them have a health index score below 30%, asset T-2, T-3, and T-6 are of particular interest with scores below 10%.

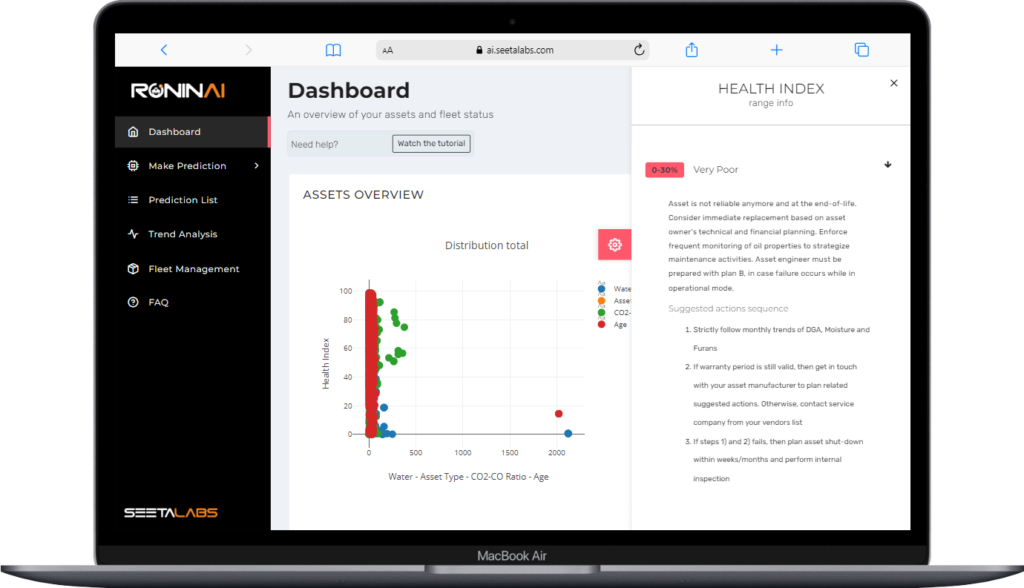

Ronin AI dashboard provides a legenda of the health indexing bands. A health index score below 30% shows that the asset is in very poor state. With negligence it may be approaching end of life sooner. As a general rule, the dashboard might suggest replacement. However, it is necessary to conduct a comprehensive technical analysis of the assets before proceeding. It is noticeable that some faults may be repairable and may not require total replacement of asset thereby saving time and money.

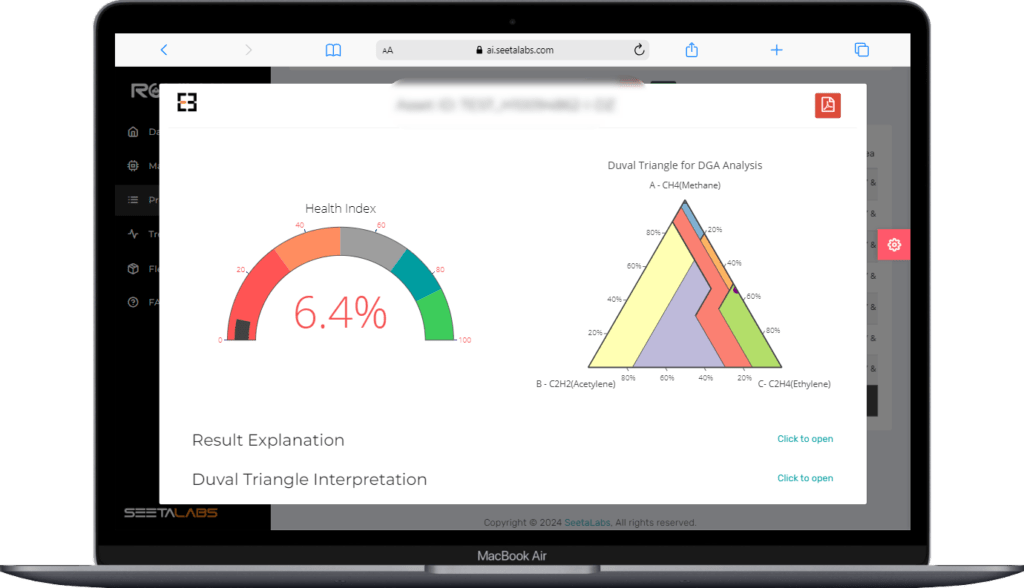

In such circumstances, it is crucial for the asset manager to determine the exact status of the said asset and decide future actions. For example, asset T-2 has the lowest index score of 6.4% and the embedded Duval’s triangle in the Ronin AI report suggests a high temperature fault in the T3 zone. Further investigation reveals that the asset T-2 may have a hot-metal fault without cellulosic involvement. In most cases such issues may arise from a bare metal connection and is often repairable.

Conclusion

An operational asset could require either maintenance, repair, refurbishment and/or replacement recommendations. A health index approach delivers this over a defined timeline. Despite a ranking strategy, transformer health index can be significantly improve with data context. While asset indexing strategies are often objective, Ronin AI dashboard provides a perfect platform for integrating various asset management techniques for a comprehensive decision. In studying a fleet of seven auto-transformers of particularly low health index (<30% as predicted by Ronin AI), the already embedded Duval’s triangle method can help in primary fault identification. Further assessment of the asset technical data helps in fault analysis and potential actions to assign. The whole action strategy takes less than an hour by an expert. This proves the usefulness of Ronin AI health indexing as a fleet screening tool and its integrated approach towards transformer asset management in a cost and time-efficient manner. If you like this post and wish to explore more then read another case study here.

Our intention is to help you choose the best recommendations for integrating health indexing strategies with fault analysis tools to boost your capabilities.

If you wish to learn more, just contact us or grab your free trial right away!