A reliability ranking system

for power transformer fleets.

RONIN AI · CIGRE TB 761 · ISO/IEC 42001:2023

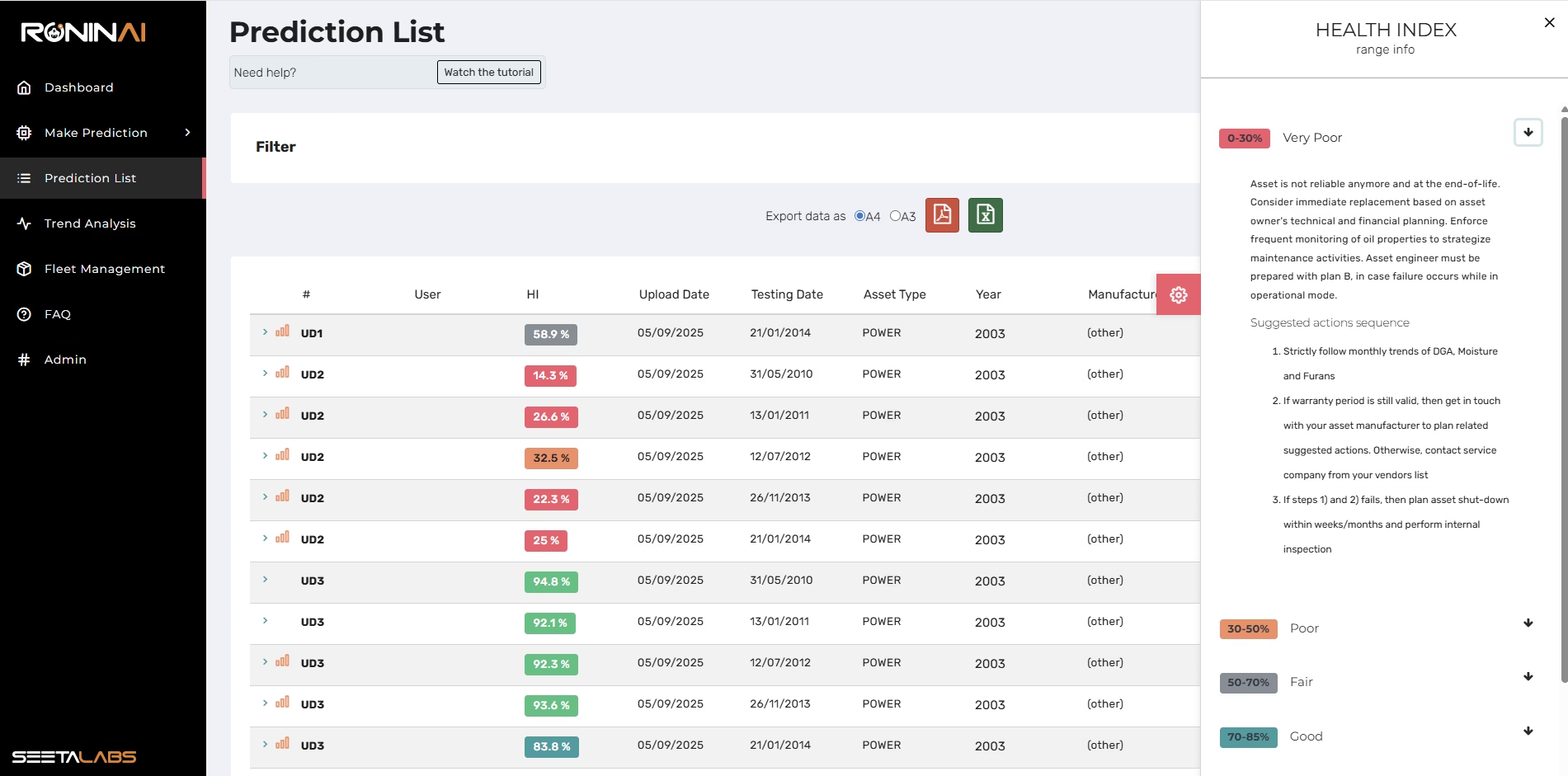

RONIN AI calculates a health index for each transformer in a fleet based on condition monitoring data. The output is a ranked list of assets by risk – objective, reproducible, and aligned with CIGRE methodology.

Instant Rankings

Upload DGA data, get fleet-wide health rankings in seconds

Works with Sparse Data

THI methodology compensates for missing parameters

CIGRE TB 761 Compliant

Industry-standard methodology, audit-ready reports

Health indexing grounded in CIGRE methodology.

THE METHOD

The health index is the central concept. RONIN AI operationalises it as a machine learning model trained on real transformer condition data.

What the health index is

CIGRE A2.44 defines transformer health index as “an overall indicator describing the condition status of a transformer that the decision maker can use to define and prioritize the required action.” It provides the conceptual and technical foundation for condition-based maintenance strategies.

How RONIN AI uses it

CIGRE A2.49 specifies that the health index can be used “to identify transformers that are most likely to fail on a timescale to plan intervention.” RONIN AI applies this directly: the output is a ranked fleet list ordered by risk, designed to support maintenance planning decisions.

A well-designed health index converts condition monitoring data into actionable remarks that accelerate maintenance decisions. RONIN AI uses it to highlight and rank transformers within a fleet on the basis of technical urgency and asset reliability. A health index should not be used to mask alarms generated from poor quality condition monitoring data – data quality is a precondition, not a variable the model compensates for.

80%

MODEL ACCURACY

80% is a design decision, not a limitation

A machine learning model that fits too closely to training data produces a high coefficient of determination on paper and poor predictive performance in the real world. In statistics, this is an overfitting problem.

RONIN AI was trained to reach 80% accuracy because the goal is generalisation across diverse transformer populations, not optimisation for a specific dataset. This makes the model robust for real-case applications across different fleet compositions, operating conditions, and maintenance histories.

RONIN AI was trained to reach 80% accuracy because the goal is generalisation across diverse transformer populations, not optimisation for a specific dataset. This makes the model robust for real-case applications across different fleet compositions, operating conditions, and maintenance histories.

Three roles. One shared output.

USE CASES

Asset managers, utility operators, and service engineers face

the same challenge: how to prioritize maintenance interventions

across large transformer fleets when budgets are limited and

downtime is costly.

Traditional time-based maintenance doesn’t reveal actual failure

risk. These are the questions they need answered.

the same challenge: how to prioritize maintenance interventions

across large transformer fleets when budgets are limited and

downtime is costly.

Traditional time-based maintenance doesn’t reveal actual failure

risk. These are the questions they need answered.

Steel Plant Manager

Challenge:

“Which transformers need attention priority?”

Steel plant with 4 furnaces, 4 substations, 2 power transformers. Sparse data on older units. Time-based monitoring doesn’t reveal which assets are actually at risk.

“Which transformers need attention priority?”

Steel plant with 4 furnaces, 4 substations, 2 power transformers. Sparse data on older units. Time-based monitoring doesn’t reveal which assets are actually at risk.

Utility Asset Manager

Challenge:

“How long before decommissioning?”

Aging GSU transformer fleet with recurring gassing issues. Budget constraints force priority ranking of critical assets. Manual assessment takes weeks.

“How long before decommissioning?”

Aging GSU transformer fleet with recurring gassing issues. Budget constraints force priority ranking of critical assets. Manual assessment takes weeks.

OEM/Service Engineer

Challenge:

“Which customer assets need immediate support?”

Radial distribution across multiple sites by manufacturer type. Fleet performs well overall, but some units underperform unexpectedly. Need to identify underperforming assets for warranty claims or field intervention.

“Which customer assets need immediate support?”

Radial distribution across multiple sites by manufacturer type. Fleet performs well overall, but some units underperform unexpectedly. Need to identify underperforming assets for warranty claims or field intervention.

Unexpected transformer failure means production downtime and millions lost.

Can’t afford to replace everything. Need data-driven intervention priorities.

Proactive support prevents customer downtime and reputation damage.

Prediction Credits

First-year all-inclusive pricing. Predictions never expire. Annual renewal (€2.000/year) required to maintain platform access and use remaining credits.

Starter

50 predictions for small fleets and pilot projects. Suitable for single-site operators running one to two assessments per year.

€8.000

/year

Billed annually

Professional

Popular

250 predictions for industrial operators and utilities managing medium-to-large transformer fleets with regular diagnostic programmes.

€144 per prediction · save 10%

€36.000

/year

Billed annually

Volume

WHITE LABEL AVAILABLE

1.000+ predictions for large utilities, OEMs, service companies and testing labs processing high volumes across multiple client fleets.

Custom

negotiated rate · best unit price

* White Label:

Deploy RONIN AI under your brand. Platform, reports, and API responses carry your logo and identity.

Ready to rank your transformer fleet by risk?

Get health index rankings in seconds. Upload DGA data, receive actionable fleet priorities based on CIGRE methodology.